With the rise in coronavirus infections, any move that reduces the spread is readily adopted. COVID-19 is not an airborne virus but rather it is spread via droplets. These viral droplets remain on several surfaces for a long time until they are sanitised. While we are on the subject of surfaces, one’s clothing can be a medium too.

Neeltje van Doremalen et al., studied the stability of COVID19 and SARS on four surfaces ( copper, plastic, cardboard and stainless steel) and aerosols and observed their decay rates. (1) Among the four surfaces, both the viruses were stable for a very short period on copper and cardboard. It is interesting that cardboard that is manufactured from natural sources such as fruit scraps or vegetable fibres like seaweed inhibits the virus from thriving for too long (2). This leads one to reach out to natural fibres to go against the virus. What are natural fibres? Natural fabrics are derived from the fibres of animal coats, plant seeds, stems and leaves, and silkworm cocoons. Research has been conducted on the antimicrobial nature of natural fibres. Bamboo fibres for textiles can be used in two ways- Natural bamboo fibre and regenerated fibres. It was suggested that natural bamboo fibres have inherent antibacterial fibres and bacteriosis agents, however recent research has denied this. But extraction of carbohydrates and other mineral nutrients from the natural fibres can help to slow down the growth of microbes, since these are essential for the growth and stability of the microbes (3).

Using the right fabric in hospitals helps to combat nosocomial infections which can be very detrimental to a patient's survival. A study was conducted at the Illinois Wesleyan University to see if clothing composition affected the number of bacteria carried on the clothing (4) . Swabs from handcuffs of the hospital staff were taken and studied which showed the number of bacterial colonies on natural fabrics was very low compared to the ones found on synthetic fabrics. Natural fabrics are not completely resistant to microbes, but harbour very less compared to synthetic fabrics.

While polyester and acrylic fabrics bind bacteria at ratios exceeding 80%, natural fabrics such as cotton bind only 10%. Cellulose based textiles bind to those bacteria that is commonly found in sweat, however synthetic fabrics bind those microbes that are not found in sweat (5)(6) There is a rise in the manufacture of antimicrobial textiles and clothing companies are continuously toiling to improve the quality of the fabrics. This leads to the overuse of synthetics and harsh chemicals which over the years proves to be harmful to not only the environment but also to the user. This is when one turns to natural antibacterial sources such as tulsi (contains eugenol), neem(azadirachtin), turmeric(curcumin), clove oil, aloe vera and pomegranate (7). Methanolic extracts from ajwain seeds (carom seeds) have proven to be an excellent antibacterial agent to certain select bacteria and also improves the wash durability (8). Silk pretreated with Moreinga olefera and subsequent dyeing with natural colouring matter imparted good antimicrobial properties. The above studies emphasises the fact that natural fabric is the better option and if pre treated with natural substances is all the more better than synthetic textiles.

India is home to many natural fibres such as cotton, silk, jute, hemp and wool. India has produced one of the world's best cotton for over four thousand years, says Rustam Mehta in his book “Masterpieces of Indian textiles” (9) .Interesting fact: a cotton textile piece was found sticking to the side of a silver vase found at Mohenjodaro. This shows that cotton existed in India from the beginning of a civilization. Muslin produced during the rule of Emperor Jahangir was so fine and exquisite and measured fifteen yards in length (9). Another type of cotton that was indigenous to India is khadi which is hand-spun and rough in texture. Mahatma Gandhi believed that India’s independence and development depended on the self reliance of its five hundred and eighty thousand villages.

For many years, it has been believed that silk originated and is the cultural heritage of China exclusively. Silk weaving in China dates back to 1650-1045 B.C, although other evidence suggests that silk textiles in China date back to a millennium earlier (10).

Archaeological evidence shows that Indians produced silk of their own which dates back to circa 2450-2000 B.C (10) Now this finding brings to light the historical notion that sericulture is exclusive to China. Silk was found in the hollows of copper-alloy ornaments in Harappa and it was recovered from steatite beads on Chanhu-Daro, two sites that were very important in the Harappa civilization.(10) Silk has been an expensive fabric and is worn only on very special occasions such as temple events, marriages, house-warmings, parties. It is also the material that is worn by the Gods too in most temples. Each part of India showcases different types of Silk- such as Kanchipuram silk, Mysore silk, Banarasi silk, each exquisite and regal in their own way. The muga silkworm which is found in Assam gives rise to Tussar silk and has a golden shine to it. This silk is not dyed and is stain resistant.

Pashmina Wool (Pictures courtesy Aaditya Kitroo, Jos & Fine)

With regard to wool, its production and use is more in the north than the south of India owing to the harsh winters that India experiences up North between the months of October and March. When we talk of wool, it would be considered rude if we did not talk about pashmina. Shawls from Pashmina are so soft and although they look thin, they provide one with enough warmth. Pashmina shawls are so fine that they can be drawn through a finger ring easily. Also these shawls exhibit excellent craftsmanship, that those who own it would definitely want to show it off!

India has an abundance of plant sources which include banana, palm, korai grass, pineapple leaf fibre, and these fibres are used in manufacturing bags, carpets, bags, coasters. Indians, although exposed to various synthetic fabrics are still inclined to natural fibres. People have been using natural fibres for a very long time and continuing to use them gives them a sense of familiarity. Over the past few years, with the “go-green” revolution making a huge impact on people, there is a rise in eco-friendly brands coming up and people definitely prefer them. Natural fibres are biodegradable, non carcinogenic and health-friendly- very attractive qualities!

To procure good quality fibres, farming techniques such as multiple cropping, intercropping, inoculating the soil with Azotobacter species of bacteria and canal retting are to be followed (11). Azotobacter is a nitrogen fixing bacteria which is turned to ammonia and further into proteins. These bacteria contribute to soil fertility. Retting and microbial action on the plants will help dissolve the pectin and lignin that hold the fibres in the plants. The retting process differs from plant to plant. Retting of Jute separates the outer stem from the inner stem and the outer stem is individualised to form a fibre. Processing of jute is quite a heavy task considering its coarse nature and this requires a lot of force to separate the reeds, as compared to cotton that is much more mild. The mechanical rollers to separate the reeds in jute are wider than for cotton. Silk cocoons are dissolved in boiling water and the long fibres are extracted and fed into the spinning wheel. Cotton fibres are separated from the seed and turned to yarn before it's woven into fabric.

Former British Prime Minister Theresa May in a saree

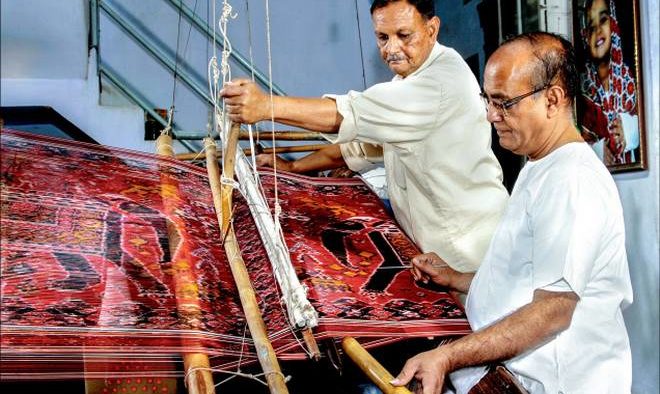

There are many techniques to turn yarn to fabric. One of the popular techniques is the Warp and Weft technique, where the warp thread is held in place in a frame or a loom and the weft threads are woven over and under the warp thread. Using the handlooms, weavers turn yarn into bed linens, silk sarees, cotton sarees, blankets, dress materials, carpets. A colourful fabric is achieved when the warp and weft threads have different coloured threads and are woven. Another beautiful technique is the Jamdani technique, wherein cotton or silk embroidery is done on muslin fabric. A mix of cotton and silk creates brocade patterns which include Himroo and Mashru- these two fabrics were created for the court muslims in Hyderabad who preferred a mix of cotton with silk and not silk alone (9) (as they considered it to be too ostentatious). This when compared to the Banarasi brocade which is purely silk is quite inferior. Other techniques involve the base fabric woven first and a pattern is printed on it. These include Batik, Bandhani, block printing, embroidery.

Handlooms in the Kullu district in Himachal Pradesh focus on wool weaving, due to the extreme winters. Kullu shawls, chaddar, blankets, kullu cap, mufflers, hand gloves. Local people there have pit looms at home and weave the wool (12)

For over 4.3 million people in India, handloom weaving is their livelihood. With power looms barging in and selling products at a very low rate, handloom weaving is taking a backstep and is putting those 4.3 million at a loss (13). The government feels that handloom weaving is outdated and unproductive. Handloom weaving is a part of the cultural heritage of India and needs to be protected from change to avoid dilution of tradition. Ritu Sethi, founder of the Craft Revival Trust and editor of the Craft Revival Encyclopedia focuses on “the social and cultural significance of handlooms, the traditional knowledge associated with its production, and the entire handloom value chain that it sustains, including those who wear and value handloom”(16) . Let's take the handlooms of Sikkim which is quite old and is primarily done by the Lepcha tribe in Sikkim. The Lepchas women learn this exceptional artform at a very young age and become so very proficient at weaving colourful yarns onto cotton fabrics (14) This is their livelihood and it provides employment to so many from the tribal community and also fulfils their daily requirements.

The Indian film industry is witnessing a wave of Indian handlooms and hand-woven traditional trends with films like Sui Dhaaga and Mallesham. Fashion designers like Gaurang Shah, Ritu Kumar, Jyoti Reddy are reviving the traditional handlooms. Jyoti Reddy has been cultivating Eri Silk in Assam for over a decade now.

“This will encourage youngsters to sit on handlooms with their weaver parents. The more educated among the handloom weaver communities will change the rules of the game. And handloom weaving will become a hobby of sorts for the elite,” predicts Jyoti.

Indian fabrics are sought out by so many countries, the USA being the single largest buyer. Other countries include UAE, Canada, Saudi Arabia, China , Turkey and Japan. India's exports of textiles and apparels is to account for 39% of the market (17). The exports basket consists of a wide range of items comprising cotton textiles, handloom textiles, wool and woolen goods, silk, jute and handicrafts including carpets. Due to the shrinking base of the European fabric manufacturers, Indian made fabrics have a good demand in the European markets (15)

Today, Indian craftsmanship remains in demand across the globe. The British appreciate the great diversity and quality of skills available in India and the ability to create innovative designs for an international clientele.

In the words of Annapurna Mamidipudi in her thesis, Towards a theory of innovation for handloom weaving in India, “Craft becomes the thread of continuity, an interactive and ongoing normal practice of peoples of both worlds who innovate in socio-technical ensembles. Every culture already knows this, if only it chooses to remember.”

REFERENCES:

- Doremalen, Morris, Holbrook, Gamble, Williamson, Tamin, Harcourt, Thornburg, Gerber, Lloyd-Smith, de Wit, Munster., Aerosol and Surface Stability of SARS-CoV-2 as Compared with SARS-CoV-1., New England Journal of Medicine

- The untapped potential of recycled cardboard

- Xi, L., Qin, D., An, X., and Wang, G. (2013). "Resistance of natural bamboo fiber to microorganisms and factors that may affect such resistance," BioRes. 8(4), 6501-6509.

- S Cotner, E Navrotski, L Sewera, V Snyder, E Richter. Diversity Of Culturable Bacteria On Natural Vs Artifical Fabrics. The Internet Journal of Microbiology. 2009 Volume 8 Number 2. 0.

- Teufel L, Pipal A, Schuster KC, Staudinger T, Redl B. Material dependent growth of human skin bacteria on textiles investigated using challenge tests and DNA genotyping. Journal of Applied Microbiology 2009;108:450-461

- Takashima M, Shirai F, Sageshima M, Ikeda N, Okamoto Y, Dohi Y. Distinctive bacteria-binding property of cloth materials. American Journal of Infection Control 2004;32:27-30

- Int. J. Life Sci. Pharma Res. 2018 Oct; 8(4): (L) 10-20

- Indian Journal of Fibre and Textile Research, Vol 36, September 2011, pp: 234-241

- A composite of Indian Textiles: Tradition and Technology, Janet Else

- NEW EVIDENCE FOR EARLY SILK IN THE INDUS CIVILIZATION., I. L. GOOD, J. M. KENOYER, R. H. MEADOW

- Extraction and Spinning of Traditional Plant Fibres., P.K. Das

- Handicrafts and Handlooms of Kullu, Himachal Pradesh., N Sharma

- Mamidipudi, A. (2016). Towards a theory of innovation in handloom weaving in India. Maastricht University.

- Handlooms and Handicrafts of Sikkim., T.P Sharma., SK Borthakur

- Textile fabrics: A global overview - Part III

- R. Seti and D. Jain, “The New Handloom Policy’s Removal of Restrictions.

- Global textile and Clothing Industry and India’s Position